Cape Town is doing a big plumbing job from December 15-17, 2025. They’re swapping old pipes for new, smart ones to make sure everyone has water. This will stop future leaks and keep the city’s water flowing smoothly. They picked this time because fewer people are around, making it easier to do this important work.

Why is Cape Town undertaking major water infrastructure maintenance in December 2025?

Cape Town is conducting critical water infrastructure upgrades between December 15-17, 2025, to replace aging 1970s pipes and valves, install advanced water meters, and test emergency power systems. This ensures a more resilient water supply for 1.2 million taps, minimizes disruptions during a quieter period, and prevents future leaks and service interruptions.

Countdown to the Great Pause: Why Three December Nights Matter

Cape Town is about to hit the pause button on its own bloodstream. Between 15 and 17 December 2025, shift crews in neon vests will freeze short stretches of the water grid so they can cut out brittle 1970s “aortas” and stitch in smarter, stronger parts. The stakes are high: vineyards above Somerset West, backyard cottages in Mitchells Plain and beach-bound tourists all drink from the same arteries. One clumsy move and the taps cough air, hotel laundry piles up, and jacarandas shed leaves on bone-dry lawns.

City planners picked the window deliberately. Schools are out, factories throttle back, and holidaymakers still haven’t peaked. Even so, every extra hour of silence costs goodwill, litres, and rand. The brief choreography must let reservoirs pre-fill, pressure re-balance, and rusty whirlpools flush away before sunrise kettles and garden sprayers click back on. Think open-heart surgery while the jogger keeps jogging.

Three jobs sit on separate limbs of the same hydraulic tree. Swap a seized gate in Helderrand, drop Africa’s most sophisticated water meter into Rocklands, then fake a blackout at Voëlvlei to see if diesel muscles can keep 220 megalitres a day moving. Engineers have rehearsed on desktop simulators, but sand, traffic and 35 °C December heat do not read PowerPoint. Residents who understand the drill can turn irritation into insurance – and maybe learn a little chemistry along the way.

Somerset West: Eight Hours Without the 300 mm “Heart Valve”

Monday night, 15 December, the leafier ridges above Somerset West will go grey. A 2.3 km cast-iron spine installed when Nixon was in office feeds roughly 4 200 properties – pools, citrus orchards and Tuscan-style roofs – through a single 300 mm valve that has jammed three times in eighteen months. Each jam shoved a pressure wave downhill, popping private vents and spawning pin-hole leaks that bleed millions of litres a year. This time the valve itself goes.

Traffic cops will first cage off 600 m of roadway barrier, because the chamber sits under a four-way swarm of holiday shoppers and wine-route Uber drivers. A 130-ton crane will then swing the 1.8-ton spindle clear while a sausage-shaped pneumatic plug balloons upstream, drying the trench so welders can slice the corroded flange. Its replacement – ductile iron, fusion-bonded epoxy, SCADA-ready actuator – will let remote engineers throttle the suburb from a drought-war room instead of a rusty wheelie handle.

Water will vanish at 20:00 and, if clay behaves, reappear around 02:00. The 5 MI Helderrand reservoir needs two calm hours to climb back above 3 bar, time enough for air pockets to burp out of hydrants at Irene and Dummer. Households should bank 25 ℓ per person for each dark hour – 200 ℓ for a family of four. PET cola bottles left on windowsills leach antimony in summer sun; better stack food-grade jerry cans or the familiar 20 ℓ “baby blue” drums and spike each with a teaspoon of unscented bleach to stay above 0.5 mg residual chlorine.

Rocklands: Finally Counting Every Drop on the Cape Flats

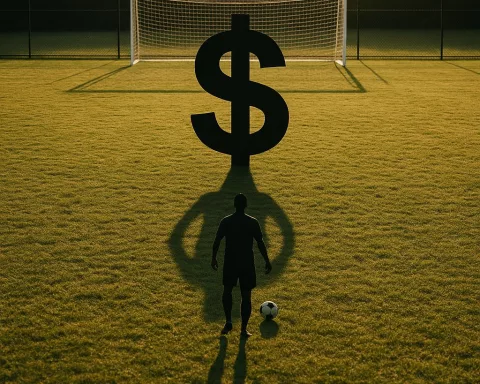

Wednesday 17 December brings the most politically charged hole. Rocklands, birthed in the late-1970s low-cost housing surge, was drawn for 8 000 souls; census tapers now point to 18 000 dwellings sprouting backyard rooms like Lego. A single 450 mm “spine” main, never designed for such density, still feeds the maze, yet only 3 200 properties wear a meter. The City will sever a 1.2 km slice between Spine–Weltevreden and Spine–Caravelle to rip out a 1960s sluice gate whose spindle has corroded to pencil thinness and bolt in a mag-flow meter that will log demand every fifteen minutes for the next decade.

Cape Flats sand hates open trenches. Crews will hammer 50 mm well-point pipes four metres down and hook twin 4-inch trash pumps capable of 90 m³/h to keep the walls from slumping. Over-pump and house foundations crack; under-pump and the trench collapses – either way the schedule slips. While pumps throb, two static 15 kl tanks will squat at Rocklands Sports Ground and an 8 kl roving tanker will tweet its coordinates @CityofCTAlerts. Bring containers; hosepipes are banned after 2018’s drought-era scuffles.

Once the mag-flow head is live, analysts will see hourly waves they have only guessed at: dawn ablution surges, twilight laundry pulses, midnight car-wash trickles. Granular data lets engineers tweak pressure management valves downstream, cutting leakage and maybe deferring a R400-million main upgrade by five years. Residents win through subtler pressure drops, lower burst frequency and, in time, fairer tariffs that reward saving instead of subsidising waste.

Voëlvlei: Sixty Electric Minutes that Test a City’s Lifeline

Also on the 17th, but 60 km inland, technicians will yank the 132 kV breaker at Voëlvlei Water Treatment Works and watch the plant sprint on its own diesel heartbeat. The works feeds 220 million litres a day – more than a quarter of Cape Town’s potable supply – so even a hiccup echoes from Durbanville to the CBD. The drill simulates the 9 March 2019 cascade blackout that left taps dry for six sweaty hours; this time engineers want confirmation that four 3.5 MW pumps will roar to life within eight seconds and keep flocculation tanks from overflowing.

Consumers should not feel a thing – Durbanville Heights reservoir carries 18 hours of strategic stock – but the directorate still begs gardeners to delay irrigation and skip the car wash between 10:00 and 11:00. Rooftop-tank hotels, dialysis clinics and private hospitals already sit on an SMS chain; they will top up on Tuesday night, not Wednesday morning. Telemetry crews will watch pressure transducers at ten remote nodes; if residual head dips below 18 m anywhere, they can manually peel off industrial loads before customers even sense a sag.

Tech, Tools and Tiny Triumphs: What Happens After the Noise

Beneath the jackhammers lies a quiet revolution. Each new valve arrives Bluetooth-ready, able to whisper cycle counts, torque signatures and micro-leak rates to a rugged tablet carried by a field ranger. Algorithms trained on Eskom’s transmission data now hunt for the tell-tale torque wiggle that precedes a blow-out – think of it as a water cardiogram that spots trouble 90 days early. The shift from “find-and-fix” to “sense-and-stalk” should trim midnight call-outs and stretch asset life by a decade.

Material science tags along. Steel spools are factory-lined with ceramic-modified epoxy that halves pipe friction; over twenty years the smoother bore will save 1.2 GWh of pumping juice – enough to power 110 homes – and cut 870 t of carbon. Scrap cast iron won’t rust in a landfill; instead, 14 t will be sliced into one-metre “art logs” and welded into street-furniture benches by a local collective, proving infrastructure can be up-cycled into Instagram moments.

Finally, citizens can spy on the whole stunt in real time. Six cigarette-pack pressure loggers clamped to Irene Road hydrants will chirp every fifteen minutes via LoRaWAN to a gateway on Helderberg College library. The open Grafana dashboard (water.capetown.gov.za/status) shows a green trace that should flat-line at 20:00 on Monday and rebound past 3 bar before dawn. If the climb stalls at 1.8 bar, someone missed a gate valve – tweet the proof, don’t just fume on Facebook.

Horses need 25–45 ℓ a day even at rest; float a tennis ball in the trough to curb evaporation and skip ice shock if a cold front gate-crashes. Aquarium buffs should plug battery air stones and delay filter cleans – chloramine can spike when the network refills. And when the first surge flings rusty threads from decades-old biofilm, bottle the ochre water, park it on a sill and watch ferric oxide settle into a rust-coloured carpet: instant colloidal-chemistry lesson for bored December kids, courtesy of the pipes beneath their feet.

Why is Cape Town undertaking major water infrastructure maintenance in December 2025?

Cape Town is conducting critical water infrastructure upgrades between December 15-17, 2025, to replace aging 1970s pipes and valves, install advanced water meters, and test emergency power systems. This ensures a more resilient water supply for 1.2 million taps, minimizes disruptions during a quieter period, and prevents future leaks and service interruptions.

Why was December 15-17, 2025 chosen for this extensive maintenance?

City planners deliberately selected this period because schools are out, factories operate at reduced capacity, and the peak holidaymaker influx has not yet occurred. This timing minimizes disruption to residents and businesses, making it easier to conduct this important work with less impact on daily life.

What specific projects are planned during the maintenance period?

Three key projects are scheduled: replacing a seized 300mm ‘heart valve’ in Helderrand (Somerset West) on December 15th, installing a sophisticated mag-flow meter in Rocklands on December 17th, and conducting an emergency power system test at the Voëlvlei Water Treatment Works on December 17th. Each project addresses critical infrastructure needs to improve water supply reliability and efficiency.

How will residents in affected areas, particularly Somerset West and Rocklands, be impacted?

In Somerset West, water will be unavailable for approximately 6 hours (20:00 to 02:00) on December 15th. Residents are advised to store 25 litres of water per person for each hour without supply. In Rocklands, two static 15kl tanks and an 8kl roving tanker will provide water at the Rocklands Sports Ground during work on December 17th, and residents should bring their own containers. Residents generally should pre-fill containers and expect potential temporary pressure drops or discoloured water as the system rebalances.

What long-term benefits will this infrastructure upgrade bring to Cape Town?

The upgrades will lead to a more resilient water supply, reduce leaks, and prevent future service interruptions by replacing aging components with smarter, stronger parts. The installation of advanced water meters and SCADA-ready actuators will allow for more granular data collection and remote pressure management, leading to improved efficiency, lower burst frequencies, and potentially fairer tariffs. The use of ceramic-modified epoxy-lined pipes will also save significant energy and reduce carbon emissions over time.

How can citizens monitor the progress of the maintenance work?

Residents can monitor the maintenance progress in real-time through an open Grafana dashboard available at water.capetown.co.za/status. This dashboard will show pressure traces from various nodes, indicating if the work is proceeding as planned and when water pressure is restored. Social media channels like @CityofCTAlerts will also provide updates, especially for the roving water tanker in Rocklands.