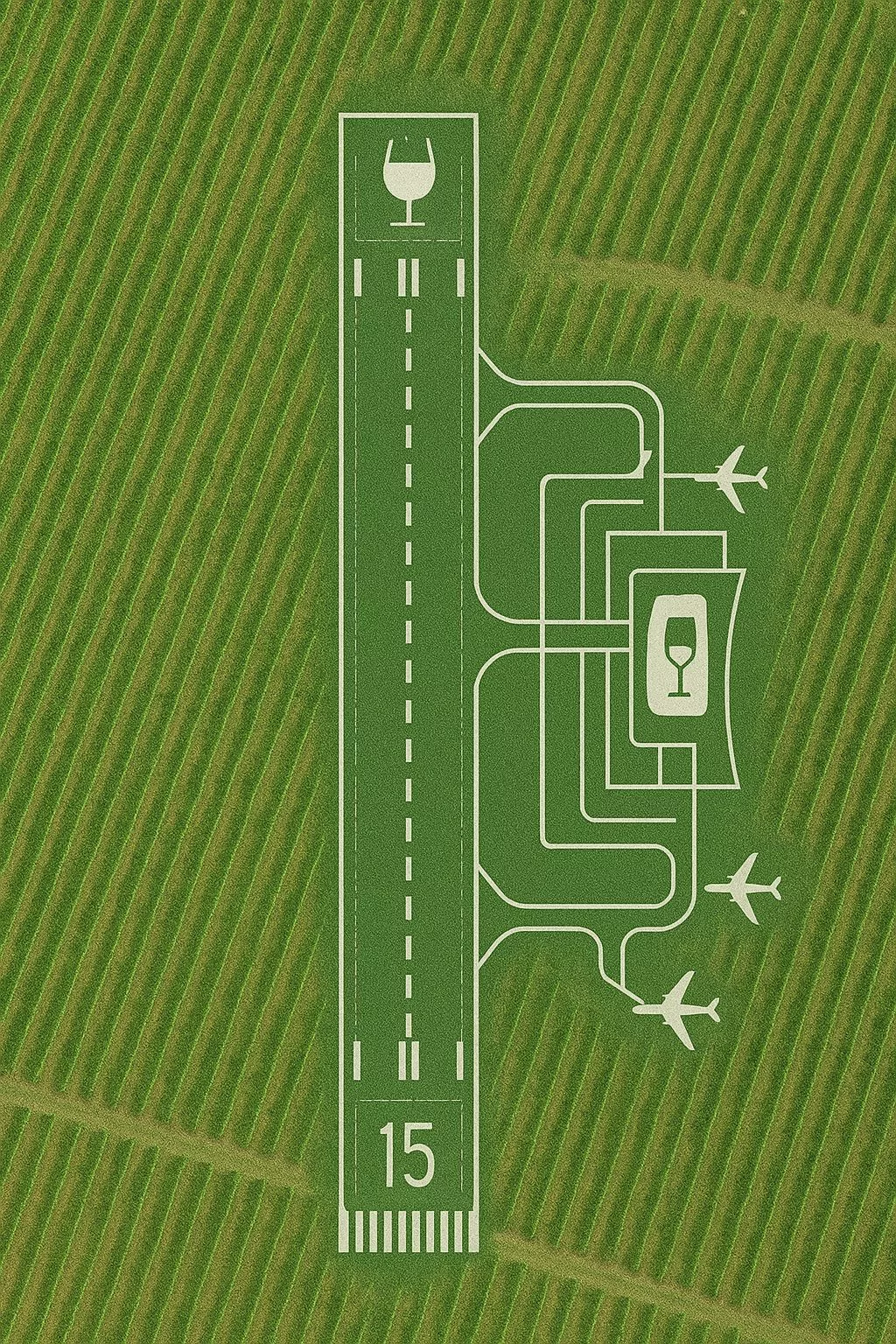

Imagine a dusty old airstrip, once just for small planes and skydivers, now becoming a super-smart airport city! This R8-billion project, Cape Winelands Airport, is building a huge runway for big cargo and passenger planes. It will have fancy wine cellars right in the terminal and special cold rooms for fresh goods. This amazing transformation will help clear traffic, boost business, and get delicious exports to the world faster.

What is the Cape Winelands Airport project?

Cape Winelands Airport is an R8-billion project transforming a small airstrip into a smart-airport city. It features a 3.2 km runway for cargo and passenger flights, a boutique terminal with wine vaults, and a freight box with pharma-grade chillers. The project aims to relieve N1 traffic and boost regional logistics and exports.

1. Why a Sheep-Skittish Airstrip Now Sits at the Centre of SA Freight Maths

Wedged between postcard vineyards outside Stellenbosch and Paarl, the old Cape Winelands strip was little more than turf, skydivers and weekend Piper Cubs. Treasury’s latest freight blueprint, however, labels the entire Drakenstein Valley a “primary logistics node”. By 2043 provincial traffic models expect 250 000 extra daily truck movements between the N1 and Saldanha; every extra minute on that corridor costs fresh-produce exporters roughly R2,4-million a week in spoiled grapes and citrus.

A 3,2 km Code 4E runway, skewed 700 m north-east to clear the Simonsberg shadow, becomes the 90-degree swivel that can unload high-value perishables off the highway and onto a cargo deck within 45 minutes of picking. In that light the R8-billion budget is not an airline vanity play; it is a regional pressure valve paid for in part by the trucks that will no longer need to queue through the N1’s Huguenot Tunnel choke point.

2. Where Every Rand Goes – a Phase-by-Phase Ledger

-

Phase 1 (2025-2028) – ±R4,1 billion*

Crews will lay 3,2 km of asphalt strong enough for a 787-9 at 98 % take-off mass, flanked by a parallel taxiway and a 30-degree high-speed exit rated for 24 instrument-approaches an hour. A 42 000 m² boutique terminal will hide 650 m² of climate-controlled wine vaults under the baggage carousel – the first time an airport builds a duty-free cellar beneath suitcases. Next door a 6 000 m² freight box gets pharma-grade chillers, customs bond and electric-vehicle docks, while a 10-million-litre borehole plant will flush loos, cool towers and irrigate the neighbouring vines. -

Phase 2 (2028-2031) – ±R2,4 billion*

Engineers lengthen the strip to 3,8 km (Code 4F) so Singapore or Seattle can be reached non-stop, and embed hydrant pits ready for liquid-hydrogen blended turbines. An 18 000 m² maintenance hangar accepts 747-8 tail doors and 40-ton overhead cranes, and Growthpoint will erect a 7 500 m² e-commerce cross-dock with 12 °C produce tunnels. -

Phase 3 (2031-2035) – ±R1,5 billion*

A 120-key business hotel will cantilever over the arrivals curb, a 35 000 m² light-industrial park will host avionics and cold-chain tenants, and an 8 MW solar farm coupled to 4 MW/16 MWh batteries will give the entire site a two-hour black-start safety net.

3. WBHO Steps Up – the Contractor That Brought You King Shaka and Gautrain Viaducts

Wilson Bayly Holmes-Ovcon’s CV already spans King Shaka’s 3,7 km runway, Cape Town Stadium’s podium and 26 km of Gautrain viaduct – work where a centimetre out means a courtroom. The group will now embed 80 planners, cost engineers and BIM modellers for an 18-month technical sprint, flanked by AECOM (air-pavements), Arup (fire-life safety) and Royal HaskoningDHV (earthworks).

A “Target-Price” pact splits any savings 60/40 in the airport’s favour, but forces WBHO to swallow the first 8 % of an overrun. That risk sandwich persuaded Lombard and Munich Re to co-write a R1,2-billion advanced-loss-of-revenues policy, the largest aviation-construction insurance placed locally since 2010 World Cup upgrades. A laser-scanned digital twin, refreshed weekly by drone, will let foremen view rebar cages through AR tablets before concrete pours – trimming rework by an estimated 2,3 %.

4. Jobs, Skills and the Hidden Extras the Brochure Forgot

Stellenbosch University’s Bureau for Economic Research counts 35 000 job-years during build, cresting at 7 900 workers in the third quarter of 2027 when paving, super-structure and fuel farms overlap. Once doors open, tourism, logistics and aircraft maintenance could sustain 100 000 livelihoods: 3 500 in cold-chain and cross-dock, 1 200 in MRO and aerospace training, and the rest induced by an extra 1,2 million visitors a year.

-

Environmental IOUs* include 86 ha of critically-endangered renosterveld locked into a 30-year conservation servitude, 3 km of watercourses turned into fire-safe bio-swales, and 340 000 t of recycled concrete crushed on-site to avoid quarry trucks.

-

Hydrogen, Wine Futures and Drones*

A KfW-backed 25-ton-per-day electrolyser will feed fuel-cell baggage tractors and, from 2030, liquid-hydrogen pits for experimental narrow-bodies – a sweet spot for South Africa’s platinum-group-metals industry. Above the cargo hall an electronic wine-futures exchange will let negociants buy containerised vintages while they still sit in Stellenbosch tanks, clear customs on the spot and lift off within six hours. A 5 km drone corridor skirting the eastern fence links to the CSIR test range, giving start-ups a beyond-visual-line-of-sight sandbox without denting instrument approaches. -

Money Stack*

Equity (R2,6 bn) comes from Harith and AIIM; DBSA and IDC supply R2,8 bn senior debt; a Vienna-listed green Eurobond adds R1,4 bn; the BRICS New Development Bank tops up R800 m mezzanine; and pre-sales of 18 ha to Growthpoint, Pivotal and PSG fetch a 30 % premium to Paarl industrial norms, sealing a finance package that is as sophisticated as any runway that will soon cross it.

[{“question”: “What is the Cape Winelands Airport project?”, “answer”: “The Cape Winelands Airport project is an R8-billion initiative to transform a small, dusty airstrip into a ‘super-smart airport city’. It will feature a 3.2 km runway capable of handling large cargo and passenger planes, a boutique terminal with integrated wine cellars, and specialized cold rooms for fresh produce. The project aims to alleviate N1 traffic congestion, boost regional economic activity, and accelerate the export of goods, particularly high-value perishables.”}, {“question”: “Why is the Cape Winelands Airport project being developed?”, “answer”: “The project is being developed to address significant logistical and economic challenges in the Western Cape. The region, particularly the Drakenstein Valley, has been identified as a ‘primary logistics node’. With provincial traffic models predicting an additional 250,000 daily truck movements between the N1 and Saldanha by 2043, the current infrastructure, including the N1’s Huguenot Tunnel choke point, is insufficient. Delays on this corridor cost fresh-produce exporters approximately R2.4 million per week in spoiled goods. The new airport will provide a vital alternative, allowing high-value perishables to be transported from farm to cargo deck within 45 minutes, thereby acting as a crucial ‘regional pressure valve’.”}, {“question”: “What are the key phases and features of the Cape Winelands Airport development?”, “answer”: “The R8-billion project is divided into three phases:\n\n Phase 1 (2025-2028) – \u00b1R4.1 billion: Construction of a 3.2 km Code 4E runway, a parallel taxiway, and a high-speed exit. A 42,000 m\u00b2 boutique terminal will include 650 m\u00b2 of climate-controlled wine vaults. A 6,000 m\u00b2 freight box will feature pharma-grade chillers and electric-vehicle docks, supported by a 10-million-liter borehole plant.\n Phase 2 (2028-2031) – \u00b1R2.4 billion: Extension of the runway to 3.8 km (Code 4F) to enable non-stop flights to distant locations like Singapore or Seattle. It will also include hydrant pits for liquid-hydrogen blended turbines. An 18,000 m\u00b2 maintenance hangar will be built, alongside a 7,500 m\u00b2 e-commerce cross-dock with 12\u00b0C produce tunnels.\n Phase 3 (2031-2035) – \u00b1R1.5 billion:* Development of a 120-key business hotel, a 35,000 m\u00b2 light-industrial park for avionics and cold-chain tenants, and an 8 MW solar farm with 4 MW/16 MWh batteries for energy independence.”}, {“question”: “Who are the main contractors and partners involved in the project?”, “answer”: “The primary contractor for the Cape Winelands Airport project is Wilson Bayly Holmes-Ovcon (WBHO), a company with a strong track record, having built King Shaka Airport’s runway and segments of the Gautrain viaducts. WBHO will deploy a team of 80 specialists for an 18-month technical sprint. They are supported by leading engineering firms: AECOM (air-pavements), Arup (fire-life safety), and Royal HaskoningDHV (earthworks). The project uses a ‘Target-Price’ pact to manage costs, with WBHO absorbing the first 8% of any overrun. Insurance for advanced loss of revenues is provided by Lombard and Munich Re, totaling R1.2 billion, marking it as a significant aviation-construction insurance policy locally since 2010.”}, {“question”: “What are the expected employment and environmental impacts of the Cape Winelands Airport?”, “answer”: “The project is expected to generate substantial employment. Stellenbosch University’s Bureau for Economic Research estimates 35,000 job-years during the construction phase, peaking at 7,900 workers in Q3 2027. Once operational, the airport is projected to support 100,000 livelihoods in tourism, logistics, and aircraft maintenance, including 3,500 in cold-chain and cross-dock operations, and 1,200 in MRO and aerospace training, also attracting an extra 1.2 million visitors annually.\n\nEnvironmentally, the project includes significant mitigation efforts: conserving 86 hectares of critically endangered renosterveld, transforming 3 km of watercourses into fire-safe bio-swales, and crushing 340,000 tons of recycled concrete on-site to reduce quarry truck traffic.”}, {“question”: “How is the Cape Winelands Airport project funded, and what innovative technologies will it incorporate?”, “answer”: “The project boasts a sophisticated finance package. Equity funding of R2.6 billion comes from Harith and AIIM. Senior debt of R2.8 billion is provided by DBSA and IDC, with a Vienna-listed green Eurobond contributing R1.4 billion. The BRICS New Development Bank supplies R800 million in mezzanine finance. Further funding is secured through pre-sales of 18 hectares to Growthpoint, Pivotal, and PSG at a 30% premium to local industrial norms.\n\nTechnologically, the airport will incorporate cutting-edge innovations: a KfW-backed 25-ton-per-day electrolyser for fuel-cell baggage tractors and future liquid-hydrogen pits for aircraft, positioning South Africa as a key player in the platinum-group-metals industry. An electronic wine-futures exchange above the cargo hall will allow real-time trading of containerized vintages. Additionally, a 5 km drone corridor will link to the CSIR test range, creating a sandbox for beyond-visual-line-of-sight drone operations without interfering with flight paths.”}]