South Africa is getting its railway system back on track with a smart move! A private company, Traxtion, bought 46 old diesel trains from New Zealand. These trains are special because they fit South Africa’s old tracks perfectly and can easily cross borders. This helps deliver goods faster and cheaper, boosting trade and making everyone happy, from farmers to big companies.

What is South Africa’s rail revolution?

South Africa’s rail revolution involves private firm Traxtion’s acquisition of 46 second-hand diesel-electric locomotives from New Zealand. This initiative aims to revitalize regional trade by overcoming capacity walls like track gauge, voltage, and border complexities, enhancing efficiency and reliability for freight transport.

1. Why a Kiwi Hand-Me-Down is Making CEOs Blink

South Africa’s 30 000 km steel spine has spent the last decade in obituary columns – cables stolen, substations torched, entire fleets parked for want of a fan belt. Yet while the public mourns the monopoly, boardrooms are studying a different script. A private firm called Traxtion just spent R3.4 billion on forty-six diesel-electric workhorses that first turned a wheel in New Zealand. The locos are not green, not new and certainly not glamorous; their moment in the sun comes from what they destroy at a single stroke: four capacity walls that have suffocated regional trade since 1994 – track gauge, voltage, border red tape and spare-parts roulette.

KiwiRail’s DC units roll on the 1 067 mm Cape gauge, so no axle has to be shaved, no wagon adapter invented. They were built to sip 3 kV DC, the same dangling wire that still powers two-fifths of Transnet’s route-kilometres, so no catenary crew is required. Event recorders, GPS pucks and EDT brakes inside each cab are already accepted by Botswana and Zimbabwe inspectors, so a loaded train can, in principle, leave the iron-ore pits of Kathu after breakfast and idle on the Victoria Falls bridge for supper – no driver change, no customs dance. In a land where a two-day border queue can erase the profit on a mango pallet, interoperability is the real precious metal.

The headline figure – forty-six locomotives – masks the ripple. Suppliers of radios, wheels, fuel and signalling software have been told to price for volume, not for a single desperate parastatal. Provincial governments along the Durban-Johannesburg corridor are suddenly polite to citrus farmers who threaten to shift 3 000 reefer containers a year to rail. Even neighbouring state railways, once allergic to anything that is not their own paint scheme, now ask for technical manuals. A second-hand asset is acting like a new market category.

2. The Maths That Turns Rust into Revenue

Transnet Freight Rail still advertises 226 million net-tonnes of annual capacity, but actual throughput has shrunk for six of the past eight years. The slump is lopsided: export coal and manganese lines still hit ninety-percent wagon-cycle rates, while the general-freight spine – 1 860 km from City Deep to the coast – has bled forty percent of its 2014 traffic. Those are the boxes Traxtion wants: fast-moving consumer goods, orange cartons, knock-down vehicle parts – cargo that pays a premium for reliability, not just fuel.

Run the calculator and the picture sharpens. A 2 800 kW diesel-electric that never has to hunt for a power socket beats the best dual-truck rig once the haul exceeds 680 km, saving eight cents per net-tonne-kilometre under March 2024 diesel and electricity tariffs. Each round-trip container shifted from N3 asphalt to steel rail keeps 1.3 tonnes of CO₂ out of the Highveld air and saves the fiscus roughly R1 100 in road-maintenance costs, according to CSIR modelling released this spring. The locos are only fifteen percent of the puzzle, but they unlock the other eighty-five.

Slots, not wheels, are the new chokepoint. Since July 2023 an interim Rail Economic Operator publishes a weekly spreadsheet of thirty-minute windows that Transnet admits it cannot fill – nineteen corridors, 2 400 opportunities a year. Miss your slot and you forfeit the next two seasons; that threat concentrates chief financial minds. Traxtion has already claimed 2 400 departures, seventy percent of them night runs between Kroonstad and Durban, and the company must have locomotives ready within seventy-two hours or watch competitors feast. A twelve-month refurbishment timeline – half the wait for a factory-fresh unit – is therefore not marketing swagger; it is survival arithmetic.

3. Building the Ecosystem: Wagons, Wages and Wi-Fi

Steel bodies matter as much as prime movers. The order book lists 920 new narrow-gauge wagons: 640 curtain-siders for palletised FMCG, 160 high-side mineral tubs and 120 container flats. Frames are cut at DCD Heavy Engineering in Vereeniging, wheel-sets arrive through a Dubai-based joint venture that keeps United Wagon Company inside sanctions-proof borders, and every axle leaves the plant tagged with RFID and GPS so that shippers can drop Transnet’s R17-per-TEU data surcharge. Ownership is inverted – Traxtion buys the asset, then leases it back by the kilometre, copying the US equipment-service-receipt model that turned American rail from basket case to world beater in the 1980s. At 18 000 km per wagon per year the fleet repays itself in 7.3 years, well inside the SADC 25-year life rule and inside most tender evaluation windows.

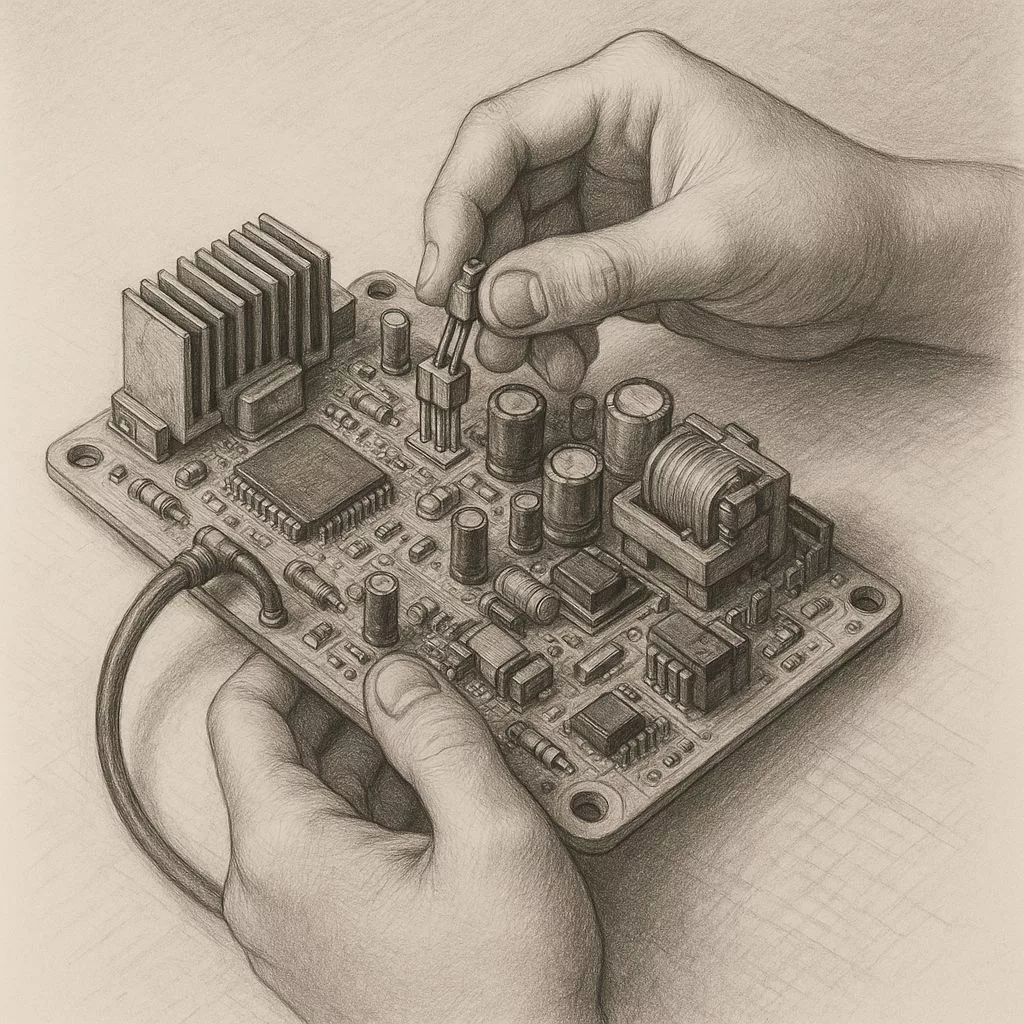

People, not metal, make trains move. Transnet’s labour creed knows two tribes – driver and assistant. Private rail must invent a third: the logistics controller who speaks fluent SAP, can placate a Port Elizabeth citrus grower at 02:00 and reroute 57 wagons around a flooded siding. The union settlement is pragmatic: thirty percent of new hires must come from Transnet’s surplus list, but entry pay is R18 000, climbing to R28 000 after five years, still below the R34 000 state benchmark. A Booysens training academy has already stamped ninety-two licences for GE Dash-8 controls; the Kiwi cab layout is close enough that a driver needs only eighteen simulator hours to re-certify, so units can enter service ninety days after docking in Durban.

Energy remains the joker. Eskom’s 132 kV umbilical cord has snapped every summer since 2019, so the upgraded locomotives carry a smart start-stop brain: idle at 400 rpm while the convoy waits, then wake to 1 050 rpm in eight seconds when the brake is released. Nine percent less diesel equals 1.8 million litres across the fleet, or R33 million at coastal wholesale prices – enough to keep shareholders calm when stage-6 darkness triggers 30 km/h permanent-way speed limits. Running three-quarters of mileage on fossil is a tactical retreat, not a surrender; the wire is still there when the electrons behave.

4. Beyond the Border: From Experiment to Export

Whiteboards in Sandton already stretch the story north. The Beitbridge-Bulawayo-Lobito line – 1 550 km of steel that ends at the Atlantic – has 18-ton axle-load, identical gauge and a 1 400 km section concessioned to a Franco-Angolan consortium desperate for dependable shunter power. Six ex-KiwiRail units could base themselves in Francistown, hauling Zambian copper and maize to Walvis Bay at 7.4 US cents per tonne-kilometre, twelve percent above the domestic tariff but secured by a Botswanan diesel-waiver worth ninety cents a litre. A 100 000-ton pilot convoy late in 2025 could scale to three million tonnes by 2027, large enough to tempt a follow-on order of twenty-five more locomotives funded through a rand-denominated green bond that Johannesburg banks are already pre-marketing.

Inside South Africa the conversation is shifting from ideology to physics. Transnet’s 2015-2021 capital drought left 2 100 km of rail older than thirty years; squat defects on the Bethlehem-Newcastle route have quadrupled since 2020. Private operators can either complain or co-fund resurfacing. Traxtion chose collaboration: a parallel-use memorandum with Passenger Rail Agency will underwrite 60 km of 60 kg/m rail on the East Rand, giving the freight operator exclusive daytime slots for five years while Metrorail keeps the night for commuters. The template needs no new law – only a joint ledger audited by the Rail Safety Regulator – and can be Xeroxed across ten more branch lines, including the Lichtenburg route that may yet ship avocados instead of memories.

Data becomes the final commodity. Every locomotive carries 900 sensors streaming oil temperature, turbo boost and traction-motor current every thirty seconds. Pooled into an anonymised lake, the feed exposes network friction in real time: curves that lunch wheels, grades that drink diesel, sidings where a manual points lever adds three hours. Traxtion will share the intelligence with Transnet’s Esselen Park research centre in exchange for preferential access to the next open-path tranche. If the quid-pro-quo survives political headwinds, South Africa will possess its first common rail data set since 1986, and the productivity gain from merely co-ordinating passing loops – today managed by WhatsApp and carbon paper – could add eight percent throughput without a single new sleeper.

No single transaction, however audacious, can mend thirty years of rust. Yet the shockwave from forty-six blue-and-yellow locomotives crossing the Indian Ocean is already rewriting tariff sheets, wage tables and wagon-lease contracts from the Cape to the Zambezi. In that sense the deal is less a purchase order than a living laboratory – one whose variables will be measured in citrus tonnes, carbon tonnes and ultimately in trust.

What is South Africa’s rail revolution?

South Africa’s rail revolution involves private firm Traxtion’s acquisition of 46 second-hand diesel-electric locomotives from New Zealand. This initiative aims to revitalize regional trade by overcoming capacity walls like track gauge, voltage, and border complexities, enhancing efficiency and reliability for freight transport.

Why did Traxtion choose second-hand locomotives from New Zealand?

Traxtion chose 46 second-hand diesel-electric locomotives from New Zealand because they are perfectly suited to South Africa’s existing 1,067 mm Cape gauge tracks. They also operate on 3 kV DC, which powers a significant portion of Transnet’s routes, eliminating the need for costly infrastructure changes. Furthermore, these locomotives are already accepted by inspectors in neighboring countries like Botswana and Zimbabwe, facilitating seamless cross-border operations and reducing delays.

How will these locomotives improve freight transport efficiency and costs?

These locomotives will significantly improve freight transport by destroying four capacity walls: track gauge, voltage, border red tape, and spare-parts availability. They are more cost-effective for hauls exceeding 680 km compared to road transport, saving approximately eight cents per net-tonne-kilometre. By shifting cargo from road to rail, each round trip saves 1.3 tonnes of CO₂ and roughly R1,100 in road maintenance costs for the fiscus. Their quick refurbishment timeline (12 months) also allows for rapid deployment, addressing the critical need for reliable transport.

What are the broader impacts of this initiative beyond just the locomotives?

This initiative has far-reaching impacts. It’s stimulating the economy by creating demand for suppliers of radios, wheels, fuel, and signalling software. Provincial governments are taking renewed interest in rail transport for goods like citrus. Neighboring state railways are also seeking technical manuals, indicating a potential for wider regional collaboration. The project also includes an order for 920 new narrow-gauge wagons and is creating new job roles, such as logistics controllers, beyond traditional driver roles.

How is Traxtion addressing challenges like electricity supply and skilled labor?

To address unreliable electricity supply (Eskom’s issues), the upgraded locomotives feature a smart start-stop system that idles at low RPM and quickly powers up, saving 1.8 million litres of diesel across the fleet annually. For skilled labor, Traxtion has a pragmatic union settlement that requires 30% of new hires to come from Transnet’s surplus list, offering competitive entry pay. A training academy is also rapidly certifying drivers for these specific locomotive controls.

How is this project looking to expand beyond South Africa’s borders?

Traxtion is already planning expansion northwards, with potential deployments on the Beitbridge-Bulawayo-Lobito line to haul Zambian copper and maize to Walvis Bay. A pilot convoy of 100,000 tons is planned for late 2025, with potential to scale to three million tonnes by 2027, which could lead to further locomotive orders. Inside South Africa, Traxtion is collaborating with Passenger Rail Agency to co-fund rail resurfacing on specific routes, securing exclusive daytime slots for freight and establishing a template for further branch line collaborations across the country.